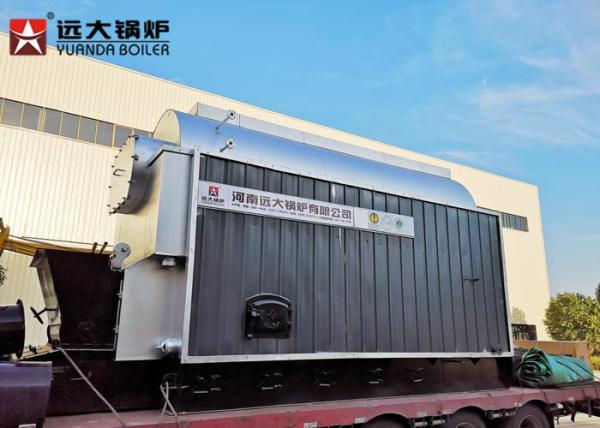

4Ton Biomass Steam Boiler Chain Grate Stoker Ricehusk Bagasse Fired

Boiler

The DZL new water-fire tube boiler is a new eco-friendly and

energy-saving product co-developed by our company and Professor Li

Zhiguang—a famous boiler expert, professor of Harbin Institute of

Technology and director of Beijing Institute of Light Boiler. It is

called as a revolution of industrial boilers by domestic and

foreign experts. Its main characteristics are as follows:

1. Sufficient and Steady Capacity

With efficient diabatic spirally corrugated tube, it is designed by

using heat transfer and flow resistance technologies of Harbin

Institute of Technology. The boiler’s actual capacity is 10-15%

higher than name plate capacity. As the physical dimension and

smoke speed of the spirally corrugated tube are rational, and the

spirally corrugated tube doesn’t form soot or wear when the boiler

normally operates, the boiler’s capacity and heat efficiency don’t

reduce with the extension of operating time;

2. Low Original Dust Discharge Concentration, Environmental

Protection and Energy Conservation

It uses new arch and hearth with large volume, the rear of the

hearth has a dust separation reversing chamber, and the unburned

dust particles fall to the hearth for secondary combustion,

corresponding to primary dedusting in the furnace. Therefore, it

ensures that the original dust discharge concentration is lower

than national permissible value, reducing fuel consumption, and

protecting the environment;

3. High Steam Quality

The optimally designed feeding apparatus reduces overhigh water

level in shell high temperature zone due to overheat; the optimally

designed steam separator facilitates vapour gravity separation, and

makes the steam humidity lower than 1%, obviously lower than

national standard of 4%;

4. Strong Water Quality Adaptability

By adopting the advanced water circulation technology, it improves

water circulation speed of high temperature zone, increases the

flow of bottom water, and avoids sundries deposition and scaling,

with stronger water quality adaptability than other furnaces,

reducing fuel consumption, and improving operating time;

5. Small Overall Dimensions and Low Boiler Room Investment Cost

The main heating surface is installed in the shell, and small

capacity boiler can cancel the rear heating surface. Its overall

dimension is obviously smaller than other boilers. The boiler below

100tons (70MW) can be arranged in single layer, making the

investment of the boiler room save more than 50% than other types;

6.Low Operating Cost, Safety and Reliability

The adoption of advanced water circulation technology and

optimization of boiler structure improve the operating conditions

of the high temperature tube plate, water wall tube and shell

bottom. In normal water quality condition, it doesn’t cause tube

explosion, tube plate cracking or shell bottom bulge.

Technical parameter sheet

| Model | Rated capacity | Rated pressure | Rated Feed water temperature | Rated steam temperature | Fuel consumption | Weight | Dimension |

| t/h | Mpa | ℃ | ℃ | kg/h | Ton | mm |

| SZH2-1.25/2.5-AII | 2 | 1.25/2.5 | 20 | 194/226 | 225/228 | 17/18.5 | 4850×2690×3468 |

| SZH4-1.25/2.5-AII | 4 | 1.25/2.5 | 20 | 194/226 | 450/462 | 22/24.8 | 5450×3040×3468 |

| SZL2-1.25/2.5-AII | 2 | 1.25/2.5 | 20 | 194/226 | 223/227 | 20/25 | 5960×2960×3468 |

| SZL4-1.25/2.5-AII | 4 | 1.25/2.5 | 20 | 194/226 | 447/453 | 28/29 | 6510×3130×3468 |

| SZL6-1.25/2.5-AII | 6 | 1.25/2.5 | 20 | 194/226 | 671/684 | 38/42 | 7830×3346×3468 |

| SZL8-1.25/2.5-AII | 8 | 1.25/2.5 | 20 | 194/226 | 781/803 | 52 | 8200×3346×3468 |

| SZL10-1.25/2.5-AII | 10 | 1.25/2.5 | 20 | 194/226 | 1113/1127 | 68 | 8500×3346×3482 |

| SZL15-1.25/2.5-AII | 15 | 1.25/2.5 | 20 | 194/226 | 1663/1686 | 30 | 9583×3400×3550 |

| SZL20-1.25/2.5-AII | 20 | 1.25/2.5 | 20 | 194/226 | 2218/2246 | 40 | 11600×3460×3520 |

Boiler application

1. Food industry: steam can be used for food disinfection, cooking;

Wine industry need to use steam;

2. Petrochemical industry: steam can be used to heat oil, to

strengthen the liquidity of oil;

3. Foam, furniture production: the steam can be used for producing

foam. When making furniture, wood needs to be dried with steam;

4. Filling block production:steam used for drying the aerated

brick;

5. Washing ironing industry: generally used in laundry, including

dry cleaning machines, dryers, washing machines, dehydration

machines, ironing machines, iron and other equipment supporting the

use;

6. Packaging machinery industry: labeling machines, sets of

standard machine;

7. Bio-chemical industry: fermentation tank, reactor, sandwich pan,

mixer, emulsifier and other equipment;

8. Food machinery industry: tofu machine, steamer, sterilization

tank, packaging machines, paint equipment, sealing machines and

other equipment;

Export Case

| export to Vietnam, Philippines,Bangladesh, Sri Lanka | SZL2-1.25-T | Coal fired steam boiler is very popular, Vietnam customer uses it

for textile industry, Philippines customers uses it for wood

processing factory, Bangladesh customer uses it for feed processing

factory, Sri Lanka customer use it for paper processing factory,

etc. |

| export to Honduras | DZL8-1.25-T | DZL model boiler is a coal/biomass fired steam boiler, high quality

steam output for usage, single drum with water-fired tube

structure, Our Hoduras customer need the 8 ton/hour steam boiler

into using. This model boiler is one with chain grate, automatic

fuel feeding and running, working life can reach 25 years,

sufficient steam supply. |

| export to Philippines | DZL2-1.25-T | 2ton wood chips fired steam boiler export to Philippines |

| export to Vietnam | SZL6-1.25-T SZL4-1.25-T | Biomass is the renewable energy, it's a excellent fuel to fire as

for some area where has rich biomass resource. SZL model boiler,

two drums with water tube , there is large furnace for fuel

burning, improve thermal efficiency. Biomass fuel can be wood

chips, bagasse, ricehusk, peanut shell, corncob,etc. SZL model

boiler is available to 1ton-40ton steam output per hour. |